Customer

Rolls-Royce, a world-leading provider of power systems and services for use on land, at sea and in the air, has established a strong position in global markets – civil aerospace, defense aerospace, marine and energy and nuclear.

Project Background

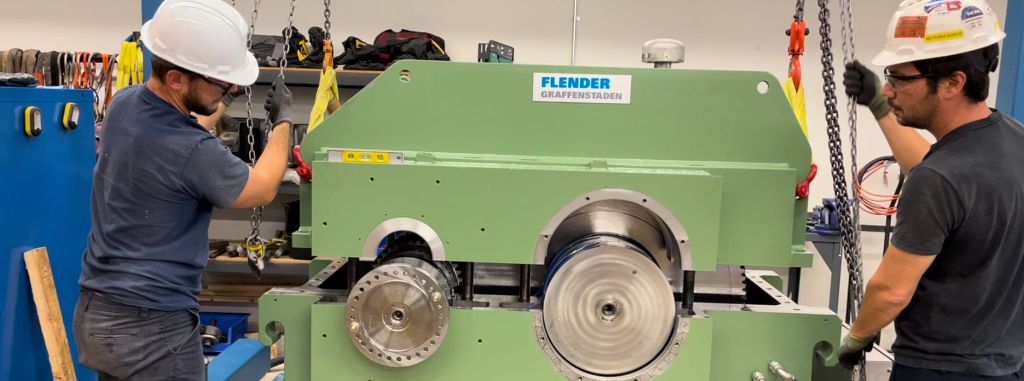

Rolls-Royce Energy division needed a decreasing gear for power generation. During the commissioning of the gear at Rolls Royce’s test facilities, the gear experienced a high vibration. Rolls Royce used FGGS field service engineers to resolve the vibration issues.

FGGS Approach

FGGS’s field service engineer was able to collect the onsite vibration data and work with Flender Graffenstaden’s engineers to determine the possible cause of vibration.

Using the years of experience FLENDER’s engineers have on vibration data, it was determined that this was an unusual vibration occurrence. After examining all possibilities it appeared the vibration probe was set in the casing at the wrong axial position resulting in a vibration reading outside of the “run out” area.

Transferred Power

The FGGS field service engineer was able to relocate the vibration probe and position it in the run out area. After the probe was mounted in the correct position the vibration issue was resolved.