CAVEX Worm Gears through FGGS provides all the parts and upgrades to your currently installed FLENDER / Siemens worm drive.

Phone: +1 (203) 268-5961

E-mail: info@fggscorp.com

With CAVEX’s purchase of the FLENDER / Siemens Worm Gear Division, CAVEX is further enabled to provide gear service and support for the energy industry. FGGS is the exclusive distributor in the US able to provide single-stage and multi-stage units in a variety of sizes. With original Flender OEM drawings, CAVEX Worm Gears can provide Drop-In replacement gear units or upgrades to fit your needs.

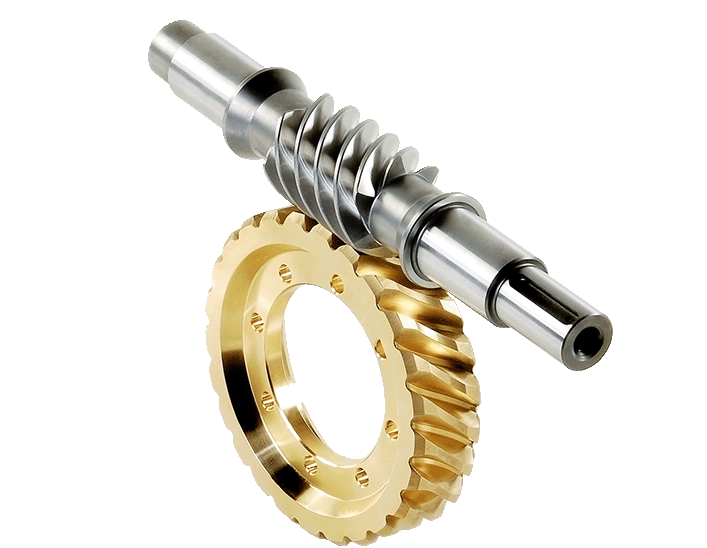

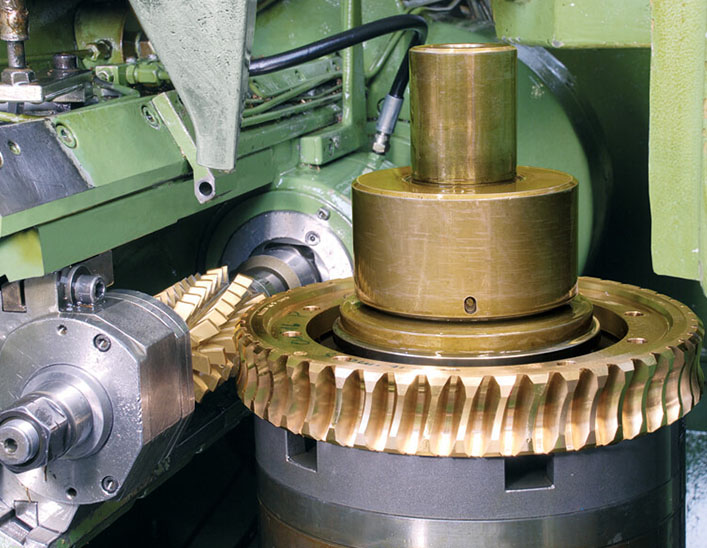

CAVEX Worm Gear Units are characterized by a low noise and impact resistant torque transmission. The hardened, cut tooth flanks of the worm shaft and the high-quality bronze of the worm wheel guarantee low wear and long lifetimes. Thanks to the gear tooth geometry in CAVEX Worm Gear Units, you’ll have a huge advantage over conventional units. The CAVEX difference is how much precision goes into making these products and how efficiently they operate. They’re continually developed to make sure the CAVEX Worm Gears is always the optimum solution. This standard of quality makes CAVEX the perfect choice for Oil & Gas power generation and much more.

CAVEX Worm Gear units can be applied to a variety of industries:

Elevators, cement mixers, belt drives, rotary drives, solar technology, food and beverage, and the steel industry all have many use cases where the CAVEX Worm Gear can be applied. Thanks to factors like high ratios, high reliability, maximum overload capability, high torque, long lifetime, and rugged design, the CAVEX Worm Gear is more suitable for any task.

Talk to a knowledgeable member of our engineer staff to find out more about the various applications these Worm Gear Units are capable of handling. No matter how sector-specific your needs are, we can find a solution for you.